Smart manufacturing isn’t merely a technological leap; it represents a transformative industrial revolution. By integrating self-perception, learning, decision-making, execution, and adaptation capabilities, it revolutionizes the manufacturing industry, optimizing resource utilization and enhancing factory productivity through scientific and technological advancement.

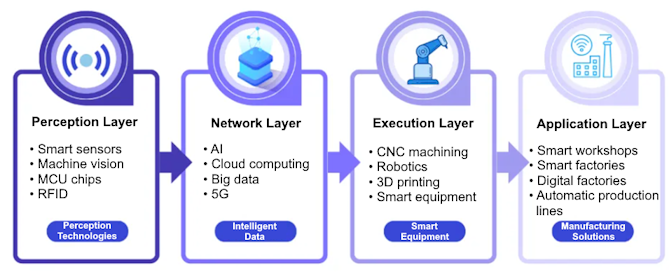

In the hierarchical structure of the industrial chain, smart manufacturing can be categorized into four layers: perception, network, execution, and application.

The perception layer incorporates smart sensors and controllers. The network layer facilitates information transmission and processing through technological advancements, such as artificial intelligence (AI), cloud computing, big data, and 5G. The execution layer involves integrated products like robots and CNC machine tools. The application layer integrates smart factories with automated production lines.

At the heart of this framework lies the network layer, acting as the "neural center" that weaves through the four layers of the architecture seamlessly. It serves vital functions:

- Utilizing information collection technologies such as MEMS sensors, smart cameras, and intelligent terminals to digitalize production processes.

- Leveraging 5G, IoT, and other communication technologies for efficient connectivity and enhanced data sharing among diverse nodes

- Harnessing cloud-edge computing and AI technologies to realize cost-effective data storage and robust massive data processing across diverse data resources, facilitating smart decision-making across production stages.

Intelligent data serves as a catalyst, establishing vertical and horizontal data chains. Vertically, it spans managerial, execution, and equipment levels within a manufacturing enterprise. Horizontally, it connects upstream and downstream companies along the industry chain, fostering business collaboration and resource integration. As a result, it effectively drives the digital transformation of the entire industrial ecosystem.

Over the past decade, RapidsDB has harnessed its independently developed core technology – an in-memory distributed computing engine – to pioneer groundbreaking software and hardware products and solutions tailored specifically for the manufacturing industry. These innovations enable real-time computation of petabyte-scale data, seamlessly facilitating industrial processes of high-precision equipment from data collection, modeling, governance to analysis, and aiding in swift intelligent application development. From facilitating rapid market response to enabling flexible supply chain management, from streamlining production equipment forecasting to ensuring stringent product quality inspection, these solutions cater to diverse use cases, empowering our customers to navigate modern industrial challenges with ease.

In a smart factory construction project, the RapidsDB team collaborated with a large-scale mining enterprise to implement RapidsDB’s intelligent manufacturing solution. This solution capitalized on RapidsDB’s new-generation digital production platform, seamlessly integrating the company’s internal and external production data and facilitating intelligent processing of vast amounts of data from heterogeneous data sources. Built upon the RapidsDB’s distributed, in-memory computing engine, this high-performance platform empowered enterprise personnel to monitor the overall factory status on a single screen, gaining real-time insights into various production details. It also empowered the management team to take data-driven approaches and make informed decisions, significantly improving operational management efficiency and ensuring a stable and safe production environment.

Moreover, in a substantial ocean port infrastructure upgrading endeavor, the RapidsDB platform served as the digital brain of the industrial IoT system. It facilitated real-time processing and analysis of unmanned vehicle data, allowing for the instantaneous detection of anomalies. The enhanced data infrastructure empowered the unmanned vehicle dispatching system to respond to queries with a remarkable 20-fold acceleration in speed.

Smart manufacturing is reshaping the global industrial landscape, and RapidsDB remains at the forefront, enabling industries to harness intelligent data fully. Through its capabilities, manufacturing processes can be reconstructed and optimized effortlessly, fostering a more competitive environment in the evolving global manufacturing arena.